For any warehouse operation, maximizing space utilization and streamlining logistics are constant goals. Standard pallet sizes play a crucial role in achieving these objectives. This comprehensive guide delves into the importance of standard pallet sizes, explores common options globally, and equips you with the knowledge to make informed decisions for your warehouse.

Why Standard Pallet Sizes Are Important for Warehouse Management

Standardizing pallet sizes offers a multitude of benefits for warehouse management. Here’s a breakdown of the key advantages:

- Optimized Storage Capacity: Warehouses designed for specific pallet dimensions allow for a maximized storage layout. Standardized pallets ensure efficient stacking, eliminating wasted space and maximizing vertical space utilization.

- Enhanced Warehouse Workflows: Consistent pallet sizes facilitate smoother workflows. Forklifts and other material handling equipment operate seamlessly with standardized pallets, minimizing delays and improving overall efficiency.

- Simplified Inventory Management: Standardized pallets make inventory tracking and management a breeze. Knowing the exact dimensions and weight capacities of pallets allows for accurate load calculations and efficient organization within the warehouse.

- Reduced Damage: Pallets with standardized dimensions minimize the risk of product damage during loading, unloading, and transportation. Consistent sizing ensures a secure fit within trucks and containers, preventing product shifting and potential damage.

- Improved Cost-Effectiveness: Standardization offers cost savings in several ways. Warehouses require fewer custom-sized pallets, minimizing purchasing costs. Additionally, standardized pallets are readily available and often more affordable than custom options.

Common Standard Pallet Sizes Used Worldwide

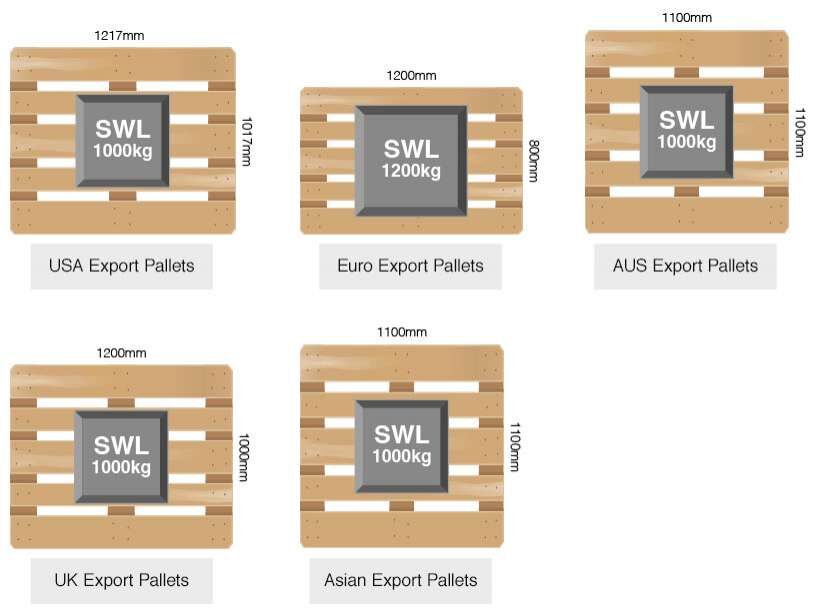

While regional variations exist, several standard pallet sizes dominate the global warehouse landscape:

- North America:

- GMA Pallet (48″ x 40″ x 3.5″): The undisputed king in North America, the GMA pallet, established by the Consumer Brands Association (formerly Grocery Manufacturers Association), is the most widely used size.

- 42″ x 42″ and 48″ x 48″ Pallets: These square pallets offer alternative options for specific storage and transportation needs within North America.

- Europe:

- Euro Pallet (1200mm x 1000mm x 144mm): The European standard pallet reigns supreme across Europe. Its dimensions perfectly match standard European truck trailers and containers, facilitating seamless international trade.

- Asia:

- 1100mm x 1100mm Pallet: A popular choice in many Asian countries, this pallet size offers compatibility with European pallets while catering to specific regional requirements.

- 1067mm x 1067mm Pallet: Another common Asian standard, this size finds application in various industries throughout the continent.

- Australia:

- Aussie Pallet (1165mm x 1165mm): Designed to maximize space utilization within Australian standard shipping containers, this pallet size is prevalent Down Under.

Factors to Consider When Choosing a Standard Pallet Size

Selecting the optimal standard pallet size for your warehouse requires careful consideration of several factors:

- Product Characteristics: The size, weight, and stacking capabilities of your products significantly influence your pallet choice. Ensure the chosen pallet size can accommodate your product load securely.

- Warehouse Layout and Storage Capacity: Analyze your warehouse dimensions and available storage space. Opt for a pallet size that maximizes vertical space utilization while enabling efficient product movement within the warehouse.

- Compatibility with Transportation: Consider the standard pallet sizes used by your transportation partners, including trucking companies and shipping containers. Choosing a compatible size streamlines loading and unloading processes.

- Material Handling Equipment: Ensure your existing forklifts and other material handling equipment can seamlessly handle the chosen pallet size. Incompatible pallet dimensions can hinder operations and necessitate equipment upgrades.

- Cost Considerations: While cost shouldn’t be the sole deciding factor, it’s essential to evaluate the availability and affordability of different standard pallet sizes in your region.

Benefits of Using Standard Pallet Sizes in Warehouse Operations

Implementing standard pallet sizes unlocks a multitude of benefits for your warehouse:

- Improved Efficiency: Standardized pallets streamline all aspects of warehouse operations, from product storage and retrieval to loading and unloading. Consistent sizing minimizes wasted time and effort, leading to increased efficiency.

- Enhanced Safety: Standardized pallets promote safer working environments. With proper training, personnel can confidently handle and maneuver pallets, reducing the risk of accidents and injuries.

- Reduced Costs: Standardizing pallets minimizes the need for custom-sized options, leading to cost savings in purchasing and maintenance. Additionally, optimized storage space utilization reduces overall warehouse footprint requirements.

- Simplified Communication and Collaboration: Standardized pallets facilitate clear communication and collaboration within your warehouse and across your supply chain. Everyone involved in the process understands the dimensions and capabilities of the pallets being used.

- Global Trade Compatibility: Choosing standard pallet sizes compatible with international shipping regulations simplifies exporting and importing products. This can provide a significant competitive advantage in today’s globalized marketplace,

Challenges and Considerations When Implementing Standard Pallet Sizes

While numerous advantages exist, transitioning to standard pallet sizes may present some challenges:

- Adapting Existing Warehouse Layout: Warehouses designed for non-standard pallet sizes might require modifications to accommodate new standard dimensions. This could involve adjusting shelving heights, rearranging storage areas, or potentially even modifying doorways for wider pallets.

- Compatibility with Existing Equipment: In some cases, existing material handling equipment might not be compatible with the chosen standard pallet size. Upgrading equipment can be a significant investment, so a cost-benefit analysis is crucial before making the switch.

- Training and Employee Buy-In: Implementing a new standard requires training employees on proper handling procedures for the chosen pallet size. Ensuring employee buy-in and adherence to new protocols are essential for a smooth transition.

- Inventory Repackaging: If your current products are packaged for non-standard pallets, you might need to consider repackaging them to optimize space utilization with the new standard size.

Best Practices for Efficient Warehouse Management Using Standard Pallet Sizes

Here are some best practices to maximize efficiency when using standard pallets in your warehouse:

- Conduct a Thorough Warehouse Analysis: Before implementing standard pallets, meticulously analyze your warehouse layout, storage capacity, and existing equipment. This will guide you in selecting the most suitable standard size.

- Develop a Comprehensive Implementation Plan: Create a well-defined plan outlining the transition process. This plan should address potential challenges, equipment upgrades (if necessary), employee training programs, and a timeline for implementation.

- Invest in Quality Pallets: Opt for high-quality pallets constructed from durable materials to ensure longevity and minimize the risk of damage during use. Consider factors like weight capacity, material composition, and overall construction quality when selecting pallets.

- Utilize Warehouse Management Systems (WMS): Leverage warehouse management systems (WMS) to optimize pallet utilization and track inventory movement efficiently. A WMS can help you design optimal storage layouts, manage pallet locations, and ensure proper stock rotation.

- Promote Continuous Improvement: Regularly evaluate your warehouse operations and identify areas for further improvement. Consider adopting lean manufacturing principles to continuously optimize space utilization and streamline workflows within your warehouse.

How to Optimize Storage and Transportation Using Standard Pallet Sizes

Standard pallet sizes offer a powerful tool to optimize storage and transportation within your supply chain:

- Maximize Vertical Space: Standardized pallets enable efficient stacking, allowing you to utilize the full vertical space within your warehouse. This optimizes storage capacity and minimizes wasted floor space.

- Space Planning and Layout Optimization: By understanding the exact dimensions of your standard pallets, you can design a well-organized warehouse layout. This facilitates efficient product placement, retrieval, and movement within the warehouse.

- Improved Load Capacity and Transportation Efficiency: Standard pallets with consistent dimensions allow for optimal truck and container loading. This minimizes wasted space during transportation and maximizes the number of products shipped per trip.

- Reduced Transportation Costs: Optimized loading capacity translates to fewer trucks or containers needed to transport the same amount of goods. This leads to significant cost savings on transportation expenses.

Tools and Technology for Managing Standard Pallet Sizes in Warehouses

Technology plays a crucial role in effectively managing standard pallets within your warehouse:

- Warehouse Management Systems (WMS): As mentioned earlier, WMS software helps optimize pallet utilization and track inventory movement. These systems can be programmed to recognize standard pallet sizes, allowing for efficient storage allocation and streamlined product tracking.

- Warehouse Design Software: Utilize warehouse design software to create a virtual model of your warehouse and experiment with different pallet layouts. This software can help you visualize the impact of standard pallet sizes on your storage capacity and overall warehouse efficiency.

- Barcode Scanners and RFID Tags: Implementing barcode scanners or RFID tags on pallets streamlines inventory management and tracking. These technologies enable real-time monitoring of pallet location and product movement within the warehouse.

By understanding the importance of standard pallet sizes, carefully selecting the right size for your operation, and implementing best practices, you can transform your warehouse into a well-oiled machine of efficiency. Standard pallets offer a powerful tool to optimize storage space, streamline workflows, and ultimately reduce costs within your supply chain.