Ever wondered how that giant stack of colorful boxes seamlessly makes its way across oceans? The secret lies in standardization, particularly when it comes to shipping container width. These robust steel behemoths adhere to specific dimensions, ensuring efficient loading, stacking, and transportation across various modes of freight. But with various container width options available, navigating the perfect fit for your cargo can feel overwhelming. Fear not, intrepid shipper! This comprehensive guide will equip you with the knowledge to conquer container logistics.

Standard Shipping Container Widths and Dimensions

Standardization is the bedrock of the global shipping industry. The International Organization for Standardization (ISO) dictates the dimensions of various container types. Here’s a breakdown of the two most crucial dimensions to consider:

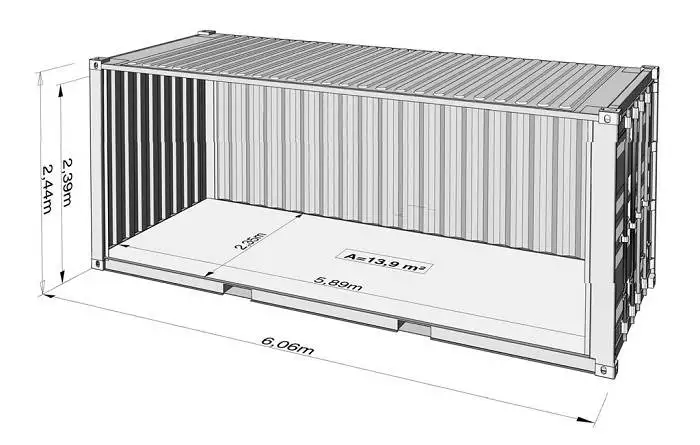

- Width: The standard shipping container width is universally 8 feet (2.43 meters). This uniform width allows containers to fit snugly on ships, trucks, and trains, optimizing space utilization.

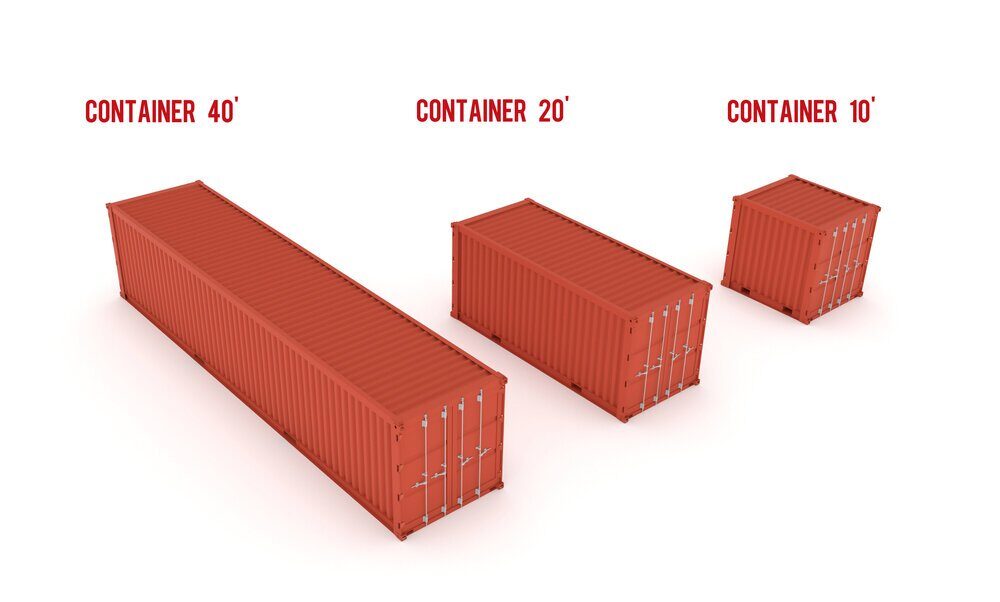

- Length: Shipping containers come in various lengths, with the most common being:

- 20 feet (6.09 meters): Ideal for smaller shipments or congested areas.

- 40 feet (12.19 meters): The industry workhorse, offering ample capacity for most cargo types.

- 45 feet (13.72 meters): A high-capacity option, primarily used in North America.

Height: While width and length are standardized, height comes in two options:

- Standard Height (8’6″ or 2.59 meters): The most common choice for general cargo.

- High Cube (9’6″ or 2.90 meters): Offers an extra foot of vertical space for taller items.

Understanding these dimensions empowers you to select the container that best suits your cargo’s specific needs.

Factors to Consider When Choosing the Right Container Width

Choosing the right container width isn’t a one-size-fits-all situation. Here are some key factors to ponder:

- Cargo Type: The shape, size, and weight of your goods are paramount. Wide, flat items like pallets or machinery may necessitate the full 8-foot width. Conversely, slender items like pipes or poles might leave significant wasted space in a standard container.

- Maximizing Space: For odd-shaped cargo, consider creative packing strategies like dunnage (filler materials) or nesting smaller items within larger ones. This helps maximize space utilization within the 8-foot width constraint.

- Destination and Regulations: Certain countries might have specific regulations regarding container dimensions. Always check with local authorities to avoid any delays or penalties at the port of entry.

- Loading and Unloading Considerations: Accessibility to the container for loading and unloading is crucial. If using side doors for access, ensure your cargo allows enough clearance within the 8-foot width.

By carefully considering these factors, you can select the optimum container width for efficient and cost-effective shipping.

Types of Cargo Suitable for Different Container Widths

The ideal container width hinges on the type of cargo you’re transporting. Here’s a quick guide:

- Full Width Utilization (8 feet): Pallets, machinery, vehicles, prefabricated structures, and bulk materials like grain or textiles.

- Slightly Less Than Full Width: Stacked boxes, furniture, appliances, and other regularly shaped items that can be strategically packed with dunnage.

- Partial Width Usage: Pipes, rods, and other slender items that can be secured using internal supports or combined with other cargo that fills the remaining space.

Remember, this is not an exhaustive list. It’s always best to consult with a shipping professional to determine the most suitable container width for your specific cargo type.

Common Shipping Container Width Options

While the standard width remains 8 feet, there are some variations to consider:

- Dry Cargo Containers: The most common type, offering the full 8-foot width for versatile cargo storage.

- Open-Top Containers: These containers have a removable top, ideal for oversized cargo that exceeds the standard height. However, the 8-foot width remains the same.

- Tank Containers: Designed for transporting liquids or gases, these containers come in various sizes, but the width typically falls within the standard 8-foot range.

Understanding these options allows you to choose the container that best suits your cargo’s unique needs.

How to Measure Cargo for Container Width Selection

Accurate cargo measurement is vital for selecting the right container width. Here’s a simple approach:

- Measure Length, Width, and Height: Precisely measure your cargo’s dimensions in all three directions (length, width, and height).

- Consider Packaging: Factor in any additional packaging materials like pallets, crates, or protective wrapping that might add to the overall dimensions.

- Account for Movement: Cargo might shift slightly during transit. Leave some wiggle room to prevent items from getting jammed or damaged within the container’s 8-foot width.

Pro Tip: It’s always better to round up measurements to the nearest whole foot. This ensures a smoother loading process and avoids any surprises when packing the container.

Tips for Maximizing Space in Shipping Containers

Even with the standardized 8-foot width, maximizing space utilization within your container is crucial for cost-effectiveness. Here are some clever tips:

- Tetris Tactics: Approach packing like a game of Tetris. Utilize the entire width by strategically arranging your cargo in a way that minimizes wasted space. Consider using interlocking shapes or nesting smaller items within larger ones.

- Palletize Whenever Possible: Pallets offer a standardized base for stacking cargo, maximizing vertical space within the 8-foot width limitation. They also facilitate easier loading and unloading with forklifts.

- Don’t Forget Dunnage: Dunnage refers to filler materials like packing peanuts, airbags, or wood blocks. These materials help secure your cargo within the 8-foot width, preventing damage from shifting during transit.

- Door Accessibility: If using side doors for loading or unloading, ensure your cargo placement allows for smooth access within the 8-foot width constraint. Consider partial disassembly or strategic stacking to create clearance for door operation.

By implementing these space-saving strategies, you can optimize your container’s 8-foot width and get the most value out of your shipment.

Cost Considerations for Different Container Widths

While the standardized width is 8 feet, the overall size and type of container can impact shipping costs. Here’s a breakdown of some factors to consider:

- Container Size: Larger containers like 40-foot models generally cost more than their 20-foot counterparts. However, if you can fill a larger container efficiently, the cost per unit of cargo might be lower.

- Destination: Shipping costs can vary depending on the origin and destination of your container. Certain routes might have higher demand for specific container sizes, leading to price fluctuations.

- Fuel Surcharges: Fuel prices can significantly impact shipping costs. Be mindful of any applicable fuel surcharges that might affect the overall cost of your container shipment.

Cost Optimization Tip: Carefully analyze your cargo volume and choose the container size that offers the best balance between capacity utilization and overall shipping cost. Consulting with a freight forwarder can help you navigate these cost considerations and select the most cost-effective option for your specific needs.

Popular Shipping Container Width Sizes and Their Uses

Now that you understand the importance of container width, let’s explore some popular sizes and their applications:

- 20-foot Dry Cargo Container (Standard Width): Ideal for smaller shipments, congested areas, or high-value cargo requiring extra security. Often used for furniture, electronics, machinery, or hazardous materials.

- 40-foot Dry Cargo Container (Standard Width): The industry workhorse, offering ample space for bulkier cargo like palletized goods, vehicles, or construction materials.

- 40-foot High Cube Container (Standard Width): Provides an extra foot of vertical space within the 8-foot width, perfect for tall items like machinery, appliances, or packaged lumber.

- Open-Top Container (Standard Width): Features a removable top, ideal for oversized cargo exceeding the standard height limitation. The 8-foot width remains the same, allowing for efficient side loading of wide or bulky items.

By understanding these popular container sizes and their suitability for different cargo types within the standard 8-foot width, you can make informed decisions for your shipping needs.