China is one of the world’s largest and most dynamic markets, offering immense opportunities for businesses across various industries. However, to succeed in this competitive and complex environment, businesses need to have efficient and effective warehousing and distribution solutions. In this article, we will explore the importance of maximizing storage and distribution in China, the current challenges faced by warehousing companies in China, and the key factors and best practices for achieving optimal warehousing solutions.

Understanding Efficient Warehousing Solutions

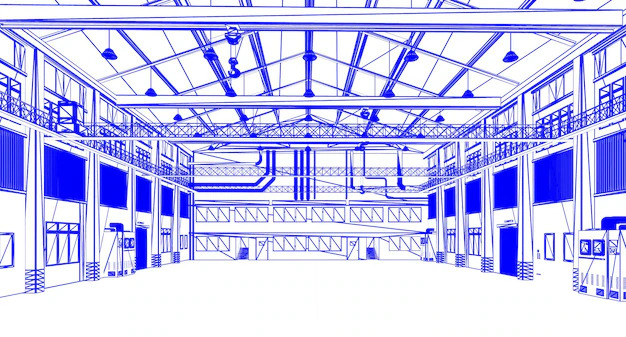

Warehousing is a vital component of the supply chain, as it involves the storage, handling, and movement of goods and products from the point of origin to the point of consumption. Warehousing solutions aim to optimize the use of space, time, and resources, while ensuring the quality, safety, and availability of the goods. Efficient warehousing solutions can provide the following benefits to businesses:

- Lower costs: By reducing the need for excess inventory, transportation, and labor, warehousing solutions can help businesses save money and improve their profitability.

- Faster delivery: By locating the warehouses close to the transportation hubs and the target markets, warehousing solutions can help businesses shorten the transit times and deliver the goods to the customers faster and more reliably.

- Higher customer satisfaction: By ensuring the availability, accuracy, and quality of the goods, warehousing solutions can help businesses meet the customer expectations and enhance their loyalty and retention.

- Better inventory management: By using technology and data to track and control the inventory levels, warehousing solutions can help businesses avoid stockouts, overstocking, and obsolescence, and optimize their inventory turnover and cash flow.

- Greater flexibility and scalability: By providing the ability to adjust the storage capacity and distribution channels according to the market demand and business needs, warehousing solutions can help businesses cope with the fluctuations and uncertainties in the supply and demand.

The Importance of Maximizing Storage and Distribution in China

China is a huge and diverse market, with a population of over 1.4 billion people and a GDP of over 14.7 trillion USD1. China is also the world’s largest exporter and the second-largest importer of goods, accounting for 13.8% and 11.5% of the global trade respectively2. China offers a unique advantage to the global supply chain, as it has an extensive infrastructure network, a large and skilled labor force, and a favorable business environment. However, China also poses some significant challenges and risks for warehousing and distribution, such as:

- High competition: China is home to many domestic and international businesses, which compete for the market share and the customer attention. To stand out from the crowd, businesses need to offer high-quality products and services, at competitive prices, and with fast and reliable delivery.

- High complexity: China is a vast and diverse country, with different regions, cultures, languages, and preferences. To cater to the different needs and expectations of the customers, businesses need to have a deep understanding of the local market and the customer behavior, and customize their products and services accordingly.

- High volatility: China is a dynamic and evolving market, with frequent changes in the consumer trends, government policies, and economic conditions. To adapt to the changing environment, businesses need to have a flexible and agile supply chain, and be able to respond quickly and effectively to the market demand and the business opportunities.

Therefore, maximizing storage and distribution efficiency in China is crucial for businesses to gain a competitive edge, increase their market share, and achieve their business goals.

Current Warehousing and Distribution Challenges in China

Despite the benefits and opportunities that China offers, warehousing and distribution in China is not without its difficulties and obstacles. Some of the common challenges that businesses face when operating in China are:

- Limited space: China has a high population density and a high urbanization rate, which means that the land and space are scarce and expensive. Finding a suitable warehouse location in China can be challenging, as businesses need to balance the cost, accessibility, and capacity of the warehouse.

- Limited infrastructure: China has been investing heavily in improving its infrastructure network, but there are still some gaps and bottlenecks in the transportation system, especially in the rural and remote areas. Transporting goods from the warehouse to the customer can be costly, time-consuming, and risky, due to the traffic congestion, road conditions, and weather factors.

- Limited technology: China has been developing its technology and innovation capabilities, but there are still some limitations and barriers in the adoption and implementation of advanced technology in the warehousing and distribution sector, such as the lack of standardization, integration, and regulation. Using technology to enhance the warehousing and distribution efficiency can be challenging, as businesses need to deal with the technical, operational, and legal issues.

- Limited talent: China has a large and skilled labor force, but there is also a high demand and a high turnover rate for the warehousing and distribution workers, especially in the peak seasons and the special events. Recruiting, training, and retaining the qualified and experienced staff can be challenging, as businesses need to offer competitive wages, benefits, and incentives.

Key Factors for Maximizing Storage and Distribution Efficiency

To overcome the challenges and achieve efficient and effective warehousing and distribution solutions in China, businesses need to consider the following key factors:

- Location: The location of the warehouse is one of the most important factors that affect the warehousing and distribution efficiency. Businesses need to choose a warehouse location that is close to the transportation hubs, such as ports, airports, and major highways, to reduce the transit times and the transportation costs. Businesses also need to choose a warehouse location that is close to their target market or key suppliers, to minimize the transportation distance and enhance the responsiveness. Additionally, businesses need to consider the availability, cost, and quality of the land and space, the infrastructure and utilities, the security and safety, and the legal and regulatory environment, when choosing a warehouse location in China.

- Size and Capacity: The size and capacity of the warehouse is another crucial factor that affects the warehousing and distribution efficiency. Businesses need to assess their current and projected inventory needs, based on their product type, volume, and seasonality, and choose a warehouse size and capacity that can accommodate their storage requirements. Businesses also need to consider the scalability and flexibility of the warehouse, and the ability to adjust the storage space and distribution channels according to the market demand and business needs. Additionally, businesses need to consider the layout and design of the warehouse, the storage equipment and systems, the inventory management and control, and the labor and operational efficiency, when choosing a warehouse size and capacity in China.

- Infrastructure: The infrastructure of the warehouse is another vital factor that affects the warehousing and distribution efficiency. Businesses need to ensure that the warehouse has the necessary infrastructure and utilities, such as electricity, water, gas, internet, and communication, to support the warehousing and distribution operations. Businesses also need to ensure that the warehouse has the appropriate transportation and logistics facilities, such as loading docks, ramps, conveyors, and trucks, to facilitate the movement and handling of the goods. Additionally, businesses need to ensure that the warehouse has the adequate security and safety measures, such as cameras, alarms, locks, and fire extinguishers, to protect the goods and the staff from theft, damage, and accidents.

- Technology: The technology of the warehouse is another essential factor that affects the warehousing and distribution efficiency. Businesses need to use technology and data to enhance the warehousing and distribution processes, such as the inventory tracking and control, the order fulfillment and delivery, and the performance measurement and improvement. Businesses also need to use technology and data to optimize the warehousing and distribution decisions, such as the demand forecasting and planning, the inventory allocation and replenishment, and the routing and scheduling. Additionally, businesses need to use technology and data to integrate the warehousing and distribution functions, such as the procurement and production, the sales and marketing, and the customer service and feedback.

Implementing Technology for Efficient Warehousing Solutions

Technology is a key enabler for achieving efficient and effective warehousing solutions in China. Technology can help businesses improve the accuracy, speed, and quality of the warehousing and distribution operations, reduce the errors, costs, and risks, and increase the customer satisfaction and loyalty. Some of the technology solutions that businesses can implement for efficient warehousing solutions in China are:

- Warehouse Management System (WMS): A WMS is a software application that helps businesses manage the warehouse operations, such as the inventory tracking and control, the order fulfillment and delivery, and the performance measurement and improvement. A WMS can help businesses automate the warehousing processes, increase the inventory visibility and accuracy, optimize the warehouse space and labor utilization, and enhance the customer service and satisfaction.

- Radio Frequency Identification (RFID): RFID is a technology that uses radio waves to identify and track the goods and products in the warehouse. RFID can help businesses improve the inventory tracking and control, reduce the errors and losses, and increase the security and safety. RFID can also help businesses streamline the warehousing processes, such as the receiving and shipping, the picking and packing, and the loading and unloading.

- Barcode Scanning: Barcode scanning is a technology that uses optical devices to read and capture the information encoded in the barcodes on the goods and products in the warehouse. Barcode scanning can help businesses improve the inventory tracking and control, reduce the errors and losses, and increase the security and safety. Barcode scanning can also help businesses speed up the warehousing processes, such as the receiving and shipping, the picking and packing, and the loading and unloading.

- Internet of Things (IoT): IoT is a technology that connects the physical objects in the warehouse, such as the goods, products, equipment, and systems,

- to the internet and each other, using sensors, actuators, and communication devices. IoT can help businesses collect and analyze the real-time data from the warehouse, such as the temperature, humidity, vibration, and location, and use it to monitor and control the warehouse conditions, optimize the warehouse operations, and prevent and solve the warehouse problems.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are technologies that use algorithms and data to perform tasks that normally require human intelligence, such as the demand forecasting and planning, the inventory allocation and replenishment, and the routing and scheduling. AI and ML can help businesses improve the warehousing and distribution decisions, reduce the uncertainty and variability, and increase the efficiency and effectiveness.

- Robotics and Automation: Robotics and automation are technologies that use machines and devices to perform the physical tasks in the warehouse, such as the picking and packing, the loading and unloading, and the movement and handling of the goods. Robotics and automation can help businesses improve the warehousing and distribution processes, reduce the labor and operational costs, and increase the speed and quality.

Best Practices for Warehouse Layout and Design in China

The layout and design of the warehouse is another important factor that affects the warehousing and distribution efficiency. The layout and design of the warehouse refers to the arrangement and organization of the warehouse space, equipment, and systems, to facilitate the storage, handling, and movement of the goods. The layout and design of the warehouse should be based on the following principles:

- Space utilization: The layout and design of the warehouse should maximize the use of the available space, and minimize the waste of space. The layout and design of the warehouse should consider the size, shape, and weight of the goods, the storage equipment and systems, the aisle width and length, and the clearance height and depth, to optimize the storage capacity and density.

- Material flow: The layout and design of the warehouse should facilitate the flow of the goods and products, and minimize the distance and time of the movement and handling. The layout and design of the warehouse should consider the inbound and outbound processes, the picking and packing processes, the loading and unloading processes, and the transportation and logistics processes, to optimize the flow direction and sequence.

- Accessibility: The layout and design of the warehouse should ensure the accessibility of the goods and products, and minimize the difficulty and complexity of the retrieval and delivery. The layout and design of the warehouse should consider the inventory turnover and frequency, the order size and type, the storage equipment and systems, and the picking and packing methods, to optimize the storage location and layout.

- Flexibility: The layout and design of the warehouse should provide the flexibility of the warehouse operations, and minimize the rigidity and inflexibility of the warehouse structure. The layout and design of the warehouse should consider the market demand and business needs, the product variety and diversity, the storage equipment and systems, and the scalability and modularity, to optimize the storage adaptability and adjustability.

Some of the best practices for warehouse layout and design in China are:

- Use vertical space: By using the vertical space of the warehouse, businesses can increase the storage capacity and density, and reduce the floor space and cost. Businesses can use different types of storage equipment and systems, such as pallet racks, mezzanines, and automated storage and retrieval systems (ASRS), to store the goods and products in multiple levels and heights.

- Use cross-docking: By using cross-docking, businesses can reduce the storage time and space, and increase the delivery speed and quality. Cross-docking is a process that involves the direct transfer of the goods and products from the inbound to the outbound vehicles, without storing them in the warehouse. Businesses can use different types of cross-docking facilities, such as consolidation centers, distribution centers, and transshipment terminals, to perform the cross-docking operations.

- Use zoning: By using zoning, businesses can improve the material flow and accessibility, and reduce the movement and handling distance and time. Zoning is a process that involves the grouping and organizing of the goods and products in the warehouse, based on their characteristics, such as the size, weight, shape, and type. Businesses can use different types of zoning methods, such as product-based zoning, activity-based zoning, and frequency-based zoning, to perform the zoning operations.

- Use slotting: By using slotting, businesses can improve the material flow and accessibility, and reduce the movement and handling difficulty and complexity. Slotting is a process that involves the assigning and arranging of the goods and products in the warehouse, based on their demand, such as the turnover, frequency, and seasonality. Businesses can use different types of slotting methods, such as fixed slotting, dynamic slotting, and hybrid slotting, to perform the slotting operations.